Products

The “A-Tool” – Model H

The Select A-Tool Model H is designed to allow deployment of data

acquisition cables (either thermocouple or fiber optic) housed inside

capillary tubing (typically stainless steel) into a carrier tubing to the

producing section of the wellbore allowing continuous pressure and

temperature monitoring of the production zone(s).

The “A-Tool”

The Select A-Tool is designed to allow deployment of data acquisition

cables (either thermocouple or fiber optic) housed inside capillary tubing

(typically stainless steel) into a carrier tubing string ran below a downhole

pump.

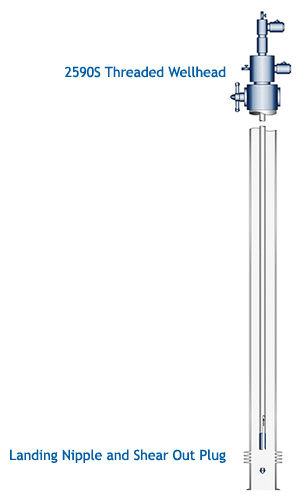

Single String Completion: Single Zone

This type of completion equipment is most commonly used on single zone wells or multi-zone wells with no commingling restrictions. The simplistic design allows coiled tubing installations to be performed without the aid of a Select Energy service technician for greater cost saving.

The integral installation thread configuration allows installation to API or ANSI casing valves without the need for crossovers or swadges while providing annular access ports for both flow and pressure monitoring. The resulting reduction of thread connections means reduced leak path points. The short stack height of this design is ideal in areas where interference with agricultural irrigation systems becomes an issue.

The versatile design allows for use in a wide range of tubing sizes. The ability to easily redress the threaded wellhead in the field offers the ultimate for cost, reliability, and function.

System components:

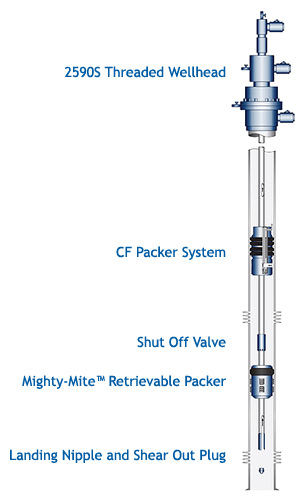

Single String Completion: Segregated

Commonly used for production or injection wells, these completions are the simplest means to isolate the casing annulus and use either retrievable or permanent packers in mechanical, hydraulic, or e-line setting configurations. Single string completions can be tailored to use plugs, sliding sleeves, on/off connectors or other accessories to meet specific customer requirements.

Single String Completion: Multi-Zone

These types of completions are commonly used in applications where commingling of like zones is permitted. The tubing and the tubing/casing annulus are utilized for independent production from the separate zones. Similar to conventional single completions, these types of wells can be configured to use plugs, sliding sleeves, on/off connectors or other accessories to meet well-specific, customer requirements.

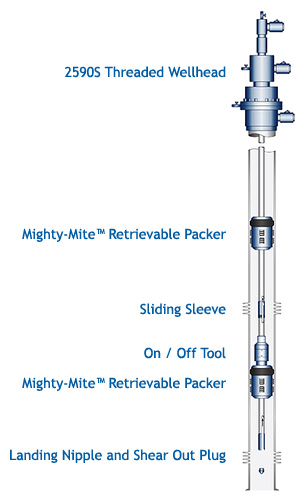

Single String Selective Completion

The single string selective completion allows commingling, separate production, isolation, testing or stimulation of individual zones. This example shows a completion using Select Energy Systems packers and a sliding sleeve to control the flow from, or into, the zone by opening and closing the sleeve above the packer.

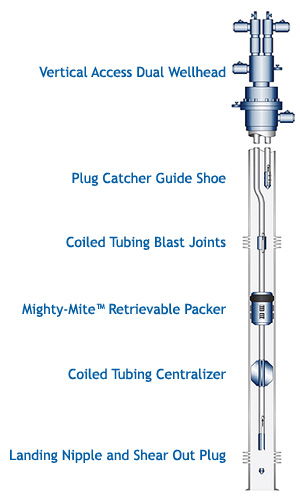

Dual String Completion: Dual Zone

These types of completions are commonly used in applications where zonal crossflow is undesirable, or regulations prohibit commingling. The lower zone is segregated by a packer and is flowed up the primary tubing string. The upper zone flows up the casing annulus or a secondary tubing string. Blast joint(s) may be run adjacent to the upper zone on the primary tubing string to prevent tubing erosion. Dual completions can be configured to meet a variety of customer well requirements.

Dual String Completion: Tri-Zone

These types of completions are commonly used in applications where zonal crossflow is undesirable, or regulations prohibit commingling. By utilizing a dual packer configuration, the lower and middle zones flow up dual tubing strings and the uppermost zone flows up the annulus. Tri-zone completions can be tailored to meet a variety of customer well requirements.

Dual String Selective Completion

This completion design increases the well’s functionality by using sliding sleeves to independently produce, stimulate, test or isolate one or more zones, using slickline or other methods to manipulate the sleeves. The example at the right highlights a quad zone completion.

WC-22 Casing Heads

WC-22 casing heads feature a versatile straight bore design that can accept a wide variety of slip and mandrel type casing hangers.

WC-22 Casing Spools

WC-22 casing spools feature a versatile straight bore design that can accept a wide variety of slip and mandrel type casing hangers.

WTCM Tubing Spools

WTCM tubing spools feature a versatile straight bore design for single and multiple completions. This design accepts all WTC series tubing hangers and easily converts from a single completion to multiple completion with the addition of alignment pin or pins.

Casing Hanger / Secondary Seals

WC-22 automatic casing hangers (wrap around) incorporate a lower pack-off, slip bowl, and slips. The lower pack-off is energized by the weight of the casing which provides a positive annular seal.

Tubing Hangers

Annular seal is lockscrew energized. Reliable compression seal controls annulus pressure during Christmas Tree installation. Lift and suspension threads are available in standard tubing sizes and threads. Threaded type H back pressure valve prep standard. Neck seals on tubing hanger provide reliable annulus sealing and isolates DHCV lines.

Tubing Head Adapters

- B-1 Tubing Head Adapter

- B2P Tubing Head Adapter

- A5P Tubing Head Adapter

Tree Caps/Tees & Crosses

Chokes / Flanges

Positive production chokes are designed for reliable flow control and maximum wear life. They are available in flanged or threaded ends in standard bore sizes from 1 13.16″ and 3 1.16″, in working pressures of 5,000 psi and 10,000 psi.

Select offers a range of companion flanges. Standard offering is 1 13.16″ thru 2 9.16″ in working pressures of 5,000 and 10,000 psi. Some sizes available in 410 stainless steel. Additional sizes available upon request. Additional types (blind and weld neck) of flanges available.

Mud Valves

Mud gate valves feature a rising stem with a “T” slotted slab gate and unique seat design that provides dependable, heavy duty performance in abrasive service conditions. It is available in flanged, butt weld, or threaded ends in standard bore sizes from 2. thru 5., in working pressures from 2,000 psi through 5,000 psi.

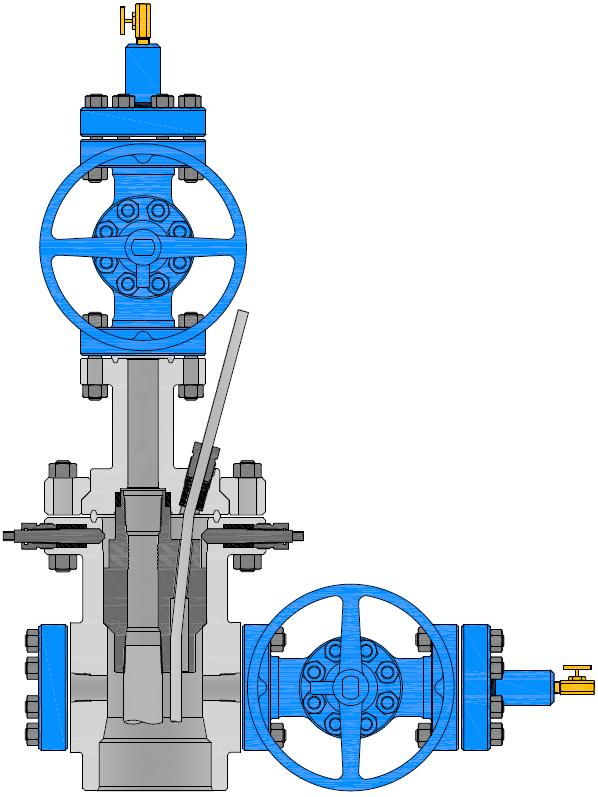

M Type Gate Valve

M gate valves feature a non-rising stem with an expanding gate design to provide safe, dependable service in a variety of environments. It is available in flanged or threaded ends in standard bore sizes from 2 1.16. thru 4 1.16. in working pressures of 3,000 psi thru 5,000 psi.

M gate valves come in 7 1.16″ with working pressures of 3,000 psi thru 5,000 psi. Gate valves with different working pressure specifications available upon request.

WM-1-Gate Valve

WM-1 gate valves feature a rising balanced stem with an expanding gate design to provide safe dependable service in a variety of environments. It is available in flanged ends in standard bore sizes from 1 13.16″ thru 4 1.16″ in 10,000 psi working pressures.

WM-1 gate valves come in 7 1.16″ with working pressures of 10,000 psi. WM-1 gate valves with different working pressure specifications available upon request.

FC Type Gate Valve

FC gate valves feature a non-rising stem with a slab gate, floating seat ring body bushing design to provide safe dependable service. It is available in flanged ends in standard bore sizes from 1 13.16. thru 7 1.16. in working pressures of 5,000 psi and 15,000 psi.

Frac Systems

Fullbore Drop Ball Wellhead and Frac Head – This surface isolation system allows full-bore passage of frac isolation balls for continuous pumping during multistage fracture treatments. Select Energy Systems integrates its wellhead product line with the frac heads all of which conform to API 6A specifications. The 70MPa (10,000psi) frac head incorporates an integral buffalo head and a ball catch system that does not require flow interruptions during well test and flow back operations. The frac head is compatible with most automatic ball drop systems on the market.

Coiled Tubing Compatible Wellhead and Frac Head – This full-bore frac head and associated wellhead completes the system for your surface isolation requirements during annular coiled tubing fracturing operations. The coiled tubing is protected in the wellhead during annular pumping operations while still allowing full-bore passage of coiled tubing deployed packers and downhole tools. The frac head is rated to 70MPa (10,000psi) and conforms to API 6A specifications.

Shallow Hang Rite

The Hang-Rite Tubing Head and Hanger provides flexibility when completing a well with either coil tubing or conventional jointed tubing. If you are uncertain about the style of completion you want to run you now have an option. The 4. or 5. through bore and unique load shoulder maintains casing drift to allow down hole equipment to pass through the tubing head. If you are snubbing conventional jointed tubing or running coil tubing in a live well condition this can be done through your 4. production valve.

SI Universal Wellhead

The SI Universal Wellhead System takes multibowl technology further than ever before. By landing two strings of pipe in one compact forged housing, the Universal System eliminates one complete BOP nipple-down/nipple-up also maintaining the initial BOP tie-in height thereby saving significant rig time and cost. Additionally, unlike most Drill-Thru multibowl systems, the SI Universal finishes with a 7-1/16. tubing head flange making completion and work-over operations indistinguishable from conventional wellhead systems. Tubing completion with the Universal uses readily available standard tubing hangers.

Universal Hang Rite

This product provides versatility when it comes to hanging a secondary tubing string in the well bore. From Jointed, Coiled or Capillary strings the Universal Hang-Rite provides options for production optimization needs. The Universal Hang-Rite was designed to land a variety of tubing strings below the master valve without reducing the ID of the thru bore while maintaining a high load capacity. With this system one string can be changed out for another and back again without having to modify any existing wellhead configurations giving it the universal status. This product has been supplied to clients that did not want to compromise their master valve and maintain a low wellhead head height.

Observation Wellhead

Observation Wellheads installations have always been a part of most standard pads. The ability to monitor the well is critical while producing. Custom configurations available.

Carbide Mills

The Select Energy carries a large range of types and sizes of carbide mills. Such as Junk Mills, Wash-Overs, Burn Shoes, Tapered Mills, Flat Bottom, and Pineapple. Select will match the mill to the application to ensure a successful milling operation.

Downhole Drilling Motor

The Select Energy Downhole Drilling Motor incorporates state of the art bearing and power sections. These Motors are inspected pre/post all jobs to insure they are in top shape for any usage.

GS Pulling and Releasing Tool

The GS Pulling and Releasing Tool is an effective means of engaging, locating and pulling on standard, internal fishing necks. The GS Tool consists of a colleted latching system that allows for maximum pull providing a high shear release on tools, or the ability to over pull any tool that may be lodge into the well bore. It’s thru bore allows circulation during deployment.

High Load Grapple Connector

The Select High Load Grapple Connector is a surface hang-off tool used to hang high coiled tubing string loads from the bottom of a tubing hanger. For example, the 2” High Load Grapple Connector has been designed to hold over 60,000# (28,000 daN) and handle pressures of 5,000 psi (35 mpa).

Motorhead Assembly

The Select Energy Motorhead Assembly is a compact tool with a multitude of features. Included are dual flapper check valves, circulating sub, and ball activated disconnects. The motorhead is a tool that can be run in conjunction with either Coiled Tubing (with dimple grapple as shown) or on Jointed Tubing.

Thermal Grapple Connector

The Thermal Grapple Connector is a tool used for connecting Coiled Tubing to either surface or sub-surface equipment in high temperature environments. Using Graph-Oil packing the Thermal Grapple can withstand temperatures of 400°f.

Low Restriction Check Valve

The Low Restriction Check Valve is typically run on the bottom of the coiled tubing for completion or workover operations. The Check Valve is designed with a large cross-sectional area above the ball and seat for maximum flow. It can be stacked for applications that require redundant sealing performance.

Flapper Check Valve

The Flapper Check Valve is connected to the coiled tubing to eliminate flow back of fluids or gas through the tubing string. The spring loaded flapper valve provides maximum flow area, while providing high performance sealing capability. The Flapper Check Valve is frequently run on drilling motor tool strings for workover and completion operations. The Flapper Check Valve provides safe operation when running coiled tubing into high-volume, high-pressure, or H2S environments.

Surface Isolation Plug (SIP)

Select Energy Systems developed the Surface Isolation Plug to meet industry demand for a method to isolate wellbore pressure inside the coiled tubing pressure, prior to retrieval from the well. The Hydraulic Setting Tool allows the operator to lubricate in and set the SIP in the tubing at surface, shutting off well bore pressure. The Surface Isolation Plug is positioned in the coiled tubing bore to allow room for a Roll-On Connector to be installed above the plug.

(SIP) Installation Tool

The Surface Isolation Plug Installation Tool is a hydraulically activated tool used to install isolation plugs in live coiled tubing strings. The plug is connected to the end of the piston shaft and run into the well, where it is set at a predetermined point near the top of coiled tubing string.

Dimple-Grapple Connector

The Dimple-Grapple Connector is an external type of connector, providing the simplicity of a grapple connector and the torque capabilities of a dimple connector. The connector is non-rotational and highly recommended when using equipment that produces torque. The Dimple-Grapple Connector can be used with downhole drilling motors, hammer mills, and any other type of hammering or jarring equipment. The coiled tubing must first be prepared for the dimple connector prior to installation by using a Dimple Connector Assembly Tool.

Dimple Connector

The Dimple Connector is a non-rotational connector used to join completion tools and workover equipment to the end of the coiled tubing. The connector is highly recommended when using tools that produce torque such as downhole motors, hammer mills, and other equipment of this type. The Dimple Connector is also used to connect nipples, packers, shear subs and other completion equipment to the coiled tubing. The coiled tubing must be prepared for the dimple connector prior to installation by using a Dimple Connector Assembly Tool.

Dimple Connector Assembly Tool

The Dimple Connector Assembly Tool is used to prepare the coiled tubing before the Dimple Connector or Dimple-Grapple Connector is installed onto the coiled tubing. The heavy-duty design uses large-socket head cap screws with rounded heads to indent the coiled tubing.

Grapple x Grapple Connector

The Grapple x Grapple Connector is used to join two strings of coiled tubing. This connector is designed for use in cases where the spool cannot take all of the coiled tubing required for a hang-off or workover and additional coiled tubing is needed.

Internal Grapple Connector

The Internal Grapple Connector is an internal connector used to connect slimline bottom hole assemblies and tools to the coiled tubing. It provides an easier method of connecting BHA’s to the coiled tubing with a slightly larger bore than a Roll-On Connector. The Internal Grapple Connector can also be used to connect or join two strings of coiled tubing, eliminating the need for welding.

Roll-On Connector

The Coiled Tubing Roll-On Connector connects two tubing strings and is designed to prevent breakage when cycling the coiled tubing over the gooseneck on the coiled tubing unit. Installation begins by removing the weld bead and burrs from the end of the coiled tubing then inserting the Roll-On connector through the end. An installation tool is used to crimp the coiled tubing over the connector, and a hardened roller wheel on the installation tool crimps the coiled tubing into the connector grooves.

Cable Clamp Assembly

The Coiled Tubing Cable Clamp Assembly is used below a Dimple Connector or Dimple-Grapple Connector when the operator has wireline inside the coiled tubing. The Cable Clamp Assembly allows the operator to run a more conventional workover without having to remove the wireline. The assembly secures the wireline safely to the side of the coiled tubing to allow pumping of fluids or dropping disconnect balls.

Snake Pin Assembly

The Snake Pin Assembly is connected to the coiled tubing and used to stab the coiled tubing into the injector, or for loading a drop spool string into the injector. One end of the Snake Pin Assembly is tapered, and the other end is connected to the coiled tubing with a swivel joint, and a flexible cable. Larger sizes incorporate a knuckle joint to reduce stress when the snake pin assembly passes over the gooseneck on the top of the injector.

Debris Filter

The Debris Filter is designed to be run in conjunction with coiled tubing tools, such as jetting nozzles, fluid control valves or ball-check valves that are sensitive to small particulate material. The filter contains a metal screen, with either slots or holes, depending on the filtering capacity required.

Knuckle Joint

The Knuckle Joint allows flexibility in the tool string for fishing operations and completion work on vertical, deviated or horizontal wells. The knuckle joint is designed for full-fluid passage for operation of tools below it, such as wash tools or fishing equipment. The tool is of a heavy-duty design and uses a primary metal to metal seal, combined with a secondary O-ring seal. Threaded connections allow the knuckle joint to be placed at the required point in the coiled tubing BHA.

Splined Knuckle Joint

The Splined Knuckle Joint offers the same functionality of the standard knuckle joint with the added feature of transmitting torque. The torque feature is ideal for bottom hole assemblies that will be using a motor, while retaining the flexibility in the tool string for fishing operations, and for completion work on vertical, deviated or horizontal wells.

Hydraulic Setting Tool

The Hydraulic Setting Tool is a pressure-activated setting tool used to set wireline retrievable plugs, permanent packers, bridge plugs, cement retainers or other types of completion equipment. The setting tool is connected to the end of the coiled tubing and run to depth. Pressuring up the tubing string activates the hydraulic pistons. The force multiplies as the pressure passes through each piston stage, providing the needed force to set the downhole equipment.

Hydraulic Setting Tool Adapter

The Hydraulic Setting Tool Adapter is run with a wireline or Hydraulic Setting Tool and provides a quick and easy method of connecting permanent or retrievable packers to the setting tool.

Pneumatic Hammer

The Pneumatic Hammer delivers downward impact when forces greater than tubing weight is required. This is beneficial when retrieving bridge plugs or other tools requiring downward force to release. The hammer can be powered with air, nitrogen or foam. The Pneumatic Hammer uses low volumes and pressures; thus it is well-suited for use with coiled tubing units outfitted with self-contained-compressors.

Circulating Port Sub

The Circulating Port Sub provides the ability to circulate above a stuck or plugged tool string. The Port Sub is equipped with rupture plugs that are activated by pumping a ball down the coiled tubing. Once the ball is on seat, an increase in pump pressure will cause the plug to rupture at the predetermined pressure, allowing circulation. The Circulating Port Sub is used with bottom hole assemblies in open hole completions or workovers utilizing downhole motors or other types of equipment.

Hydraulic Release Sub

The Coiled Tubing Hydraulic Release Sub provides a surface controlled method of releasing the coiled tubing from the tool string. It is a ball-operated Release Sub with latching lugs and splined torque lugs, specifically designed for use with rotating wash tools or other applications that transmit torque.

Rotational Safety Shear Sub

The Rotational Safety Shear Sub is used above bottom hole assemblies which, in operation, must rotate independently of the coiled tubing. The two-piece unit uses shear screws to hold a preset force value, determined by type, quantity and shear rating of the screws.

Non Rotating Safety Shear Sub

The Select Non-Rotating Safety Shear Sub was developed for use with stationary downhole equipment that develops rotational torque. The shear sub is installed in the tool string between the coiled tubing and the downhole tool. An example would be an ESP (electric submersible pump), run on small diameter coil, or polyethylene tubing, which upon startup, if allowed to rotate, would cause twisting and subsequent failure of the power cable.

Run Through Shear Sub

The Coiled Tubing Run Through Shear Sub has a standard safety shear and fish neck for use above a tension set packer. The bidirectional slip and seal set, above the shear mechanism, locks the shear sub and packer to the coiled tubing at any point. With this system, the tension packer, equipped with the Shear Sub is retained in the lubricator tube while the desired length of coiled tubing is run through the packer into the wellbore.

Adjustable Wash Tool

The Adjustable Wash Tool is run on the bottom of the coiled tubing string. The Wash Tool has a threaded connection and can be run with a variety of connections, check valves or other equipment. The tool can be adjusted to many different spray configurations for depth washing, de-scaling, perforation clean up, chemical washes or debris clean-out. By simply turning the adjustable body, the cleaning fluids can be directed in a fanning method or angled as required; thus, there is no need to have multiple nozzles in inventory.

Rotating Wash Tool

The Coiled Tubing Rotating Wash Tool is connected to the bottom of the coiled tubing and works as a jetting tool. The wash tool is designed so that fluid or pressure passes through the tool and out of the wash nozzle. The configuration of the jetting ports, combined with the pressure, rotates the nozzle. This rotating action has proven to be very successful when performing horizontal clean-outs, de-scaling casing or tubing, chemical washes on the perforations, and tubing cutting.

Wash Nozzles

The Wash Nozzle is located at the bottom of the coiled tubing and has a threaded connection so it can be run with connectors, check valves or other equipment. There are many configurations with different hole sizes and angles depending on the application.

Lantern Work Window

The Lantern Style, J-Slot Work Window is a service tool used on the wellhead during shallow well, coiled tubing completions. This tool provides an access point where the coiled tubing can be exposed to install landing equipment without disconnecting coiled tubing service equipment.

Hydraulic Work Window

The Hydraulic Style Work Window is installed above the coiled tubing quad BOP or Coiled Tubing Hanger pack-off element and ensures safe coiled tubing hang-off and other coiled tubing operational procedures. After the coiled tubing is landed at the desired depth, the annulus pressure is controlled with the quad BOP or pack-off element on the Coiled Tubing Hanger.

Threaded Work Window

The Threaded Style Work Window is installed above the coiled tubing quad BOP or hanger pack-off element and ensures safe coiled tubing hang-offs or other operations. After the coiled tubing is landed at the desired depth, the annulus pressure is controlled with the quad BOP or pack-off element on the hanger.

2590S Threaded Wellhead

The 2590S coiled tubing wellhead is installed directly on the casing master valve, using standard casing threads. The design includes a 2″ LP annular flow port and a 0.5″ NPT gauge port.

2590S Union Wellhead

The integral union 2590S wellhead is designed to be run in conjunction with a full opening hydraulic annular control valve. This design allows downhole assemblies larger than the diameter of the coiled tubing to be deployed in the well. The design includes a 2″ LP annular flow port, as well as a 0.5″ NPT gauge port.

Model DN Wellhead

The model DN wellhead is designed for use with coiled or jointed tubing and eliminates the need for a full-opening master valve on the production casing.

Short Base Dual Wellhead

The Short Base Dual Wellhead provides a means for hanging two coiled tubing strings in a well and provides maximum safety and versatility at a low installed height. When used in conjunction with a hydraulic annular control valve, downhole equipment larger than the diameter of the coiled tubing can be installed or retrieved.

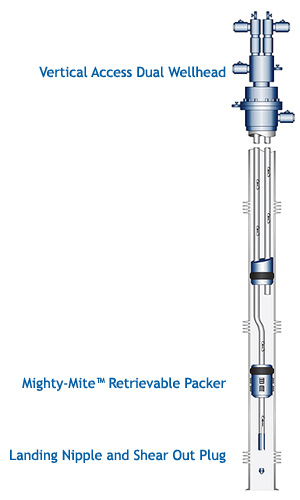

Vertical Access Dual Wellhead

The Vertical Access Dual Wellhead provides a means for hanging two coiled tubing strings. The integral pack-off and slip design, along with the unique upper valve swivel connections, provides maximum safety and versatility at a low installed height.

Flanged Wellhead

The Flanged Wellhead system is primarily used where coiled tubing is to be installed on existing wells. By design, the hanger and optional flow tee assembly become part of the original wellhead. The hanger, and slip and seal set can be manufactured for compatibility with various well conditions, including high temperature and high-pressure.

Model 2590R Threaded Hanger

The 2590R Threaded Hanger has set the standard for reliability and economy for coiled tubing completions. The 2590R is a compact hanger used as a strip-thru style with the added feature of a hydraulic pack-off.

2590R-2 and 2590R-3 Threaded Hanger

The 2590R-2 and 2590R-3 hangers provide the same proven reliability of the 2590S and 2590R hangers but allow coil tubing sizes up to 2-3/8″.

Model 2590S Threaded Hanger

The 2590S Threaded Hanger is designed for lower pressure wells and handles coiled tubing sizes up to 1.75.. Like the 2590R, the primary seal is enacted as the string weight compresses the packing element through the slip cone. The lock-down cap provides additional compression force on the slips and packing element for a secure pressure seal against the coiled tubing. The steel alloy retaining ring securely retains the packing element in the body. It can be removed easily to facilitate field replacement of the packing element.

Model DN Threaded Hanger

The work-through style hanger body uses a two-piece split seal and slip assembly that attaches to the coiled tubing string after it is run in and is at hang-off depth. The slip and seal assembly is fastened to the coiled tubing string and lowered into the hanger bore to seat on a shoulder in the hanger bore, and then it is locked in place with anchor bolts. During well completion operations, a Select 5. ID pressure window and 5. ID Annular Control Valve are used to lubricate the slip and seal assembly into the lock-down position.

Short Base Dual Hanger

The Short Base Dual Hanger provides a means of landing dual-coiled tubing strings or, used in single-string segregated application, as a clean-out access to the casing annulus above a packer. Installation of the dual hanger to the annular control valve is easily achieved with the integral hammer union.

Vertical Access Dual String Hanger

The Vertical Access Dual String Hanger permits the installation of larger-coiled tubing strings in the well. By design, the tubing strings remain near-vertical for easy access.

Triple String Hanger Base

The Select Triple Base Hanger is a unique innovation for deployment of a downhole hydraulic powered pump for dewatering gas wells. The hydraulic pump is deployed into the well simultaneously on three coiled tubing strings. The completion consists of two strings that carry hydraulic power fluid and one string for fluid production.

CT Split Flanged Hanger

The CT Split Seal Flanged Hanger uses the quad BOP of the coiled tubing service unit to seal well pressure and support the string weight, while the slip and seal assembly is being installed on the tubing string. A pressure window is installed above the quad BOP. The slip rams of the quad BOP hold the string weight, while the pipe rams contain well pressure. With the anchor bolt lock-down system, positive sealing is assured regardless of string weight. After the slip and seal set is installed in the hanger body, push force from the injector is applied to the string.

CT Flanged Hanger

The CT Flanged Hanger may be used with higher surface pressure, with or without the quad BOP system, to install the coiled tubing string. When used without the quad BOP, the integral hydraulic pack-off provides a positive seal on the tubing string, while the injector and reel brake of the coiled tubing service unit hold the string weight during slip installation and removal.

AutoCoil Hanger

The AutoCoil Hanger is a self-contained mechanical hanger that uses an automatic slip assembly to anchor and lock the coiled tubing from upward or downward movement in the well. The AutoCoil Hanger eliminates the need of an access window, thereby improving performance, safety and time efficiency on coil hang-off operations. A stripper element at the top of the hanger prevents debris from falling alongside the coil, eliminating potential problems when setting the slips.

Hydra Tubing Head

The Hydra Tubing Head is a unique side-entry product that allows coiled tubing access to the casing annulus for dewatering or clean-out operations. The design allows coiled tubing deployment through the side-entry port, utilizing a coiled tubing unit; thus eliminating the need for a service rig to pull/run the jointed pipe. Multiple side outlets provide the option for data acquisition, telemetry, or monitoring of well conditions, such as temperature and pressure.

Adjustable Thread-On Casing Head

The Select Energy Adjustable Thread-On Casing Head provides a cost-effective method for isolating the production/surface casing annulus. The Casing Head is threaded directly onto the surface casing with either a pin or box-down configuration. Sealing plates provide an annular surface barrier that may be adjusted to seal against the production casing, even in situations where the production casing is not centralized within the surface casing.

Fixed Thread-On Casing Head

The Select Energy Fixed Thread-On Casing Head provides a cost-effective method for isolating the production/surface casing annulus. The Casing Head is threaded directly onto the surface casing with either a pin or box-down configuration. Sealing is provided by O-rings contacting the production casing. The installation requires no welding on either the surface or production casing strings, eliminating potential cracks and inspection costs.

Hydraulic Annular Control Valve

The Hydraulic Annular Control Valve has been developed to provide annular control in well completions with coiled tubing. The full bore configuration allows large OD tools to be incorporated in the tubing string. When installed initially on new completions, or when re-completing existing wells, the hydraulic annular control valve provides well control and downhole tool options not possible with conventional wellhead valves.

Safety Set

Dual Barrier CT Hanger

The Safety Set Dual Barrier Coiled Tubing Hanger is an API flanged Coiled Tubing Hanger designed to provide a high level of safety and integrity for single or dual barrier requirements in all wellbore conditions.

Arrowset Production Packer

The Select Energy Arrowset I-X Wireline Set Production Packer is a retrievable, double grip production packer. A conversion of the Arrowset I-X that has over 50 years of success in the oilfield. The Arrowset I-X is one of the most versatile tools on the market today.

Casing Scraper

The Select Casing Scraper is used to remove foreign matter on the inside casing wall (of casing or tubing) in order to provide a smooth clean casing I.D. for running sub-surface equipment (such as packers). The Casing Scraper features a one piece body with full 360o casing I.D. cover-age provided by six spring loaded Scraper Blades. The design also features a large bypass area around and between the blades for ease of circulating.

On / Off Tool

The Select Energy On / Off Tool enables the tubing string to be disconnected above a packer for zonal isolation, tubing retrieval, and temporary zone abandonment. The neck of the tool contains an internal lock profile for landing a wireline plug to provide zonal isolation below the packer.

Permanent Seal Bore Packer

The Select Permanent Seal Bore Packer is an economical medium performance Permanent Packer.

It may be wireline set using an E-4 Setting Assembly, or hydraulically set on tubing using a B Setting Tool (or equivalent). The 114 mm C Permanent Packer may be set on endless tubing using an N Setting Tool (or equivalent).

Retrievable Seal Bore Packer

The Select Retrievable Seal Bore Packer combines the features of a Wireline Set Packer with the versatility of a Retrievable Packer and is mainly used in production and testing applications.

Seating Nipples

Select Energy carries a variety of Seating Nipples. Typically used in such instances as, pump seats, instrumentation seats, and depth location.

Sizes available for tubing 2-3/8” and up, with a variety of profile styles (ie. X, XN, R, and F).

Mighty-Mite™ Retrievable Packer

The Mighty-Mite™ Retrievable Packer is a highly reliable tool designed specifically for coiled tubing conveyed applications. The compact design features a built-in hydraulic set and lock mechanism. Straight tension applied to the packer shears the inner mandrel at a predetermined value, unsetting the packer. The release mechanism operates independently of the set mechanism resulting in a positive release. This allows low release shear values to be used when string tension is critical.

CF Packer System

The Select Energy Systems Concentric Flow Packer is a coiled tubing deployed packer system designed to allow three zones to be segregated and produced through two separate flow paths.

Model S Retrievable Tubing Packer

The Select Model S Hydraulic Retrievable Tubing Packer combines the advantages of a wireline set permanent packer with the versatility of a retrievable packer. This reliable packer is suited for most production, testing or stimulation applications. The Model S Hydraulic Retrievable Tubing Packer is also ideal for coiled tubing hang-offs or extensions. The Model S Hydraulic Retrievable Tubing Packer is run in and set hydraulically on jointed or coiled tubing using the Select Model A Running Tool.

Model TI Packer

The Model TI Packer is a compact, economical, and rugged packer for use in shallow production or injection installations. It is ideally suited for applications where pressure differential from below is expected.

This packer features an adjustable shear-type safety relecker. The shear release system is located below the packing element with stanase system which is used to release the padard factory-set shears.

Locator Seal Assembly

The Select Locating Seal Assembly provides a means to locate and seal coiled tubing within conventional production tubing. The seal assembly features a Lip-Seal Packing Unit and an optional built-in contingency shear disconnect. A pump off plug prevents well pressure from entering the coiled tubing while running in.

Locator Seal Sub

The Locator Seal Sub comes with a No-Go, designed to limit the downhole travel of the seals in a packer or profile nipple. The Seal Sub is made up to the packer and usually has a tailpipe and other accessories such as nipples, wireline re-entry guides or other equipment installed with it. Coiled tubing is normally landed in compression to prevent seals from moving upward, and additional seals can be added to ensure sealing in the Seal Sub.

Latching Seal Assembly

The Select Latching Seal Assembly provides a means to latch and seal a coiled tubing velocity string inside conventional production tubing. The seal assembly features a rugged Lip-Seal Packing Unit and a shear style Latching Collet to anchor and isolate the coiled tubing.

Pro-Lok Latching Seal Mandrel

The Pro-Lok Latching Seal Mandrel was developed by Select Energy Systems for efficiency and economy in the completion of segregated zone wells. The Pro-Lok is made up to the coiled tubing string using a slip-type tubing connector or alternately, a roll-on nipple. A tail joint and any required tools such as pump-out plugs or landing nipples can be installed below the mandrel.

Tubing Entry Guide

The Tubing Entry Guide is attached to the top end of a landed coiled tubing string prior to installing the production valve and Flo-Tee. The Entry Guide remains in the valve cavity below the gate mechanism or in the Tubing Nipple when using threaded wellhead components. The top end of the Entry Guide is beveled, eliminating any flat spots and directing equipment to the tubing bore. The Tubing Entry Guide is held in place by set screws and easily removed when the tubing string is to be hoisted from the wellbore.

Coiled Tubing Blast Joints

Blast Joints are used in the tubing string to protect the tubing from the abrasive action of the flowing well. Typically positioned across from the perforations, the blast joint wall section is thicker, resulting in a larger OD but still maintaining the equivalent ID of the tubing.

Coiled Tubing Centralizer

The Coiled Tubing Centralizer minimizes the natural curvature of the coiled tubing string, allowing the smooth passage of wireline tools, or other equipment through the ID of the coiled tubing. When equipped with a Select Landing Nipple, the beveled guide on the bottom ensures re-entry of suspended recorder instruments.

Centralizer Recorder Carrier

Primarily used for single packerless completions, the Coiled Tubing Centralizer Recorder Carrier securely locates a wireline recorder in the wellbore for long-term pressure and temperature surveys; protecting the recorder from potential damage and eliminating the need to suspend wireline in the well during long-term testing.

Coiled Tubing Recorder Carrier

Primarily used with packer completions, the Coiled Tubing Recorder Carrier securely locates a recorder in the wellbore for long-term pressure and temperature surveys; protecting the recorder from potential damage and eliminating the need to suspend wireline in the well during long-term testing. The recorder lands below a perforated section of the rigid Carrier, eliminating any restriction of the tubing ID.

Pump-Off Check Valve

The Pump-Off Check Valve is run on the bottom end of the coiled tubing during workovers or completion operations. The Check Valve provides a one-way flow for clean-out fluids such as N2 or CO2, to be pumped down the coil string. When used on completion installations, the valve eliminates an extra coiled tubing clean-out trip by unloading or cleaning to well bottom, prior to hang-off operations. When flow up the tubing is required, a ball is dropped and the coil string is pressured to shear release the Pump-Off Check Valve from the coiled tubing.

Landing Nipple And Drop Dart

The Landing Nipple can be used with either a Pump-out Plug or Drop Dart to isolate the wellbore pressure from the ID of a coiled tubing string. On live well deployments, the Pump Off Plug is installed in the bottom of the Landing Nipple and the tubing string is pressured to blow off the plug at a predetermined value. An optional Plug Catcher can be installed with the Nipple to retain the Pump Off Plug after it is released. The Drop Dart is allowed to free-fall down the tubing and latch into the Landing Nipple to shut off the ID of the coiled tubing string during retrieval.

Landing Nipple and Shear Out Plug

Select Energy Systems supplies Shear-Out Plugs for all sizes of Landing Nipples. The Shear Plug system is used most commonly to allow setting of hydraulic set packers. It can also be used to maintain a fluid column in the coiled tubing string as it is being run in the well.

Plug Catcher Guide Shoe

The Plug Catcher Guide Shoe contains a plug to isolate the wellbore pressure from the coil tubing ID during run-in. After hang-off of the string, air, N2 or fluid pressure is introduced through the production valve at surface to overbalance bottom hole pressure to pump off the plug. The plug falls to the bottom of the catcher cavity, allowing production through the ports and up the coiled tubing string. Because the plug is retained in the catcher cavity, it will not interfere with the function or removal of equipment farther down the wellbore.

Retrievable Drop Dart

The Retrievable Drop Dart isolates the coiled tubing ID for retrieval or repositioning of coiled tubing that has been hung off in a wellbore. The Dart is used in conjunction with a Landing Nipple for sealing and is run and retrieved with wireline.

Sliding Sleeve

The sliding sleeve is a downhole flow control tool installed on the coiled tubing string. Communication between the annulus and the tubing can be established by shifting a sleeve from a closed to open position using wireline or coiled tubing methods.

HDPE External Grapple Connector

The Select External Grapple Connector provides a means to connect tools to High Density Polyethylene (HDPE) coiled tubing strings without restricting the inner diameter of the tubing. The connector is specifically engineered to grip the outer diameter of the HDPE tubing with a one-piece slip, designed to limit radial forces that could damage or collapse the HDPE coiled tubing.

HDPE Internal Connector

The Select Internal Connector for High Density Polyethylene (HDPE) coiled tubing is a fast and cost-effective means of connecting HDPE coiled tubing strings. The Internal Connector is designed with opposing threads that when inserted into the HDPE tubing and rotated, draw the coiled tubing ends together against the large OD section of the connector.

HDPE Support Sleeve

The Support Sleeve provides collapse-resistance and ensures long-term reliable pack-off and suspension of HDPE tubing. When HDPE tubing is used as a velocity string, the tubing is run to depth and hung-off in a Select Coiled Tubing Hanger and pack-off assembly. The HDPE coiled tubing is supported by positioning the smooth section of the Support Sleeve adjacent to the packing element in the hanger. The hanger element may now be fully energized without risk of collapsing the tubing.

On / Off Tool

The On/Off tool is designed specifically for coiled tubing operation where it is desirable to disconnect the tubing string from a downhole packer. The unique indexing “J” design allows separation or reconnection by coiled tubing reciprocation.

Enhanced Velocity String System (EVSS)

The Enhanced Velocity String System (EVSS) is an integrated design approach to optimize wellbore configurations. The system is designed to extend the economic life of gas wells which may become loaded with produced fluids. The purpose of the EVSS is to configure the wellbore to allow for a number of production scenarios. These production scenarios may include any combination of slug unloading, jet assisted fluid lifting and multiple flow path velocity string production.

WR Bridge Plug

Select Energy Systems Retrievable Bridge Plug is a wireline or hydraulic set bridge plug, used to temporarily seal tubulars in any situation where a bridge plug is to be run and retrieved under pressure. The Bridge Plug combines the advantages of wireline accuracy with simple and reliable retrieval. The Retrievable Bridge Plug is commonly used for zonal isolation during well testing, fracturing, acidizing, or wellhead repair.

Permanent Bridge Plug

The Bridge Plug is an economical, fully drillable plug for applications where a 35 MPa (5,000 psi) plug is sufficient. The Bridge Plug is suitable for well abandonments or zone suspensions. It is designed for running and setting with an E-4 E-Line setting tool, or on regular coiled tubing, using a hydraulic setting tool.