Products - wellheads

WC-22 Casing Heads

WC-22 casing heads feature a versatile straight bore design that can accept a wide variety of slip and mandrel type casing hangers.

WC-22 Casing Spools

WC-22 casing spools feature a versatile straight bore design that can accept a wide variety of slip and mandrel type casing hangers.

WTCM Tubing Spools

WTCM tubing spools feature a versatile straight bore design for single and multiple completions. This design accepts all WTC series tubing hangers and easily converts from a single completion to multiple completion with the addition of alignment pin or pins.

Casing Hanger / Secondary Seals

WC-22 automatic casing hangers (wrap around) incorporate a lower pack-off, slip bowl, and slips. The lower pack-off is energized by the weight of the casing which provides a positive annular seal.

Tubing Hangers

Annular seal is lockscrew energized. Reliable compression seal controls annulus pressure during Christmas Tree installation. Lift and suspension threads are available in standard tubing sizes and threads. Threaded type H back pressure valve prep standard. Neck seals on tubing hanger provide reliable annulus sealing and isolates DHCV lines.

Tubing Head Adapters

- B-1 Tubing Head Adapter

- B2P Tubing Head Adapter

- A5P Tubing Head Adapter

Chokes / Flanges

Positive production chokes are designed for reliable flow control and maximum wear life. They are available in flanged or threaded ends in standard bore sizes from 1 13.16″ and 3 1.16″, in working pressures of 5,000 psi and 10,000 psi.

Select offers a range of companion flanges. Standard offering is 1 13.16″ thru 2 9.16″ in working pressures of 5,000 and 10,000 psi. Some sizes available in 410 stainless steel. Additional sizes available upon request. Additional types (blind and weld neck) of flanges available.

Mud Valves

Mud gate valves feature a rising stem with a “T” slotted slab gate and unique seat design that provides dependable, heavy duty performance in abrasive service conditions. It is available in flanged, butt weld, or threaded ends in standard bore sizes from 2. thru 5., in working pressures from 2,000 psi through 5,000 psi.

M Type Gate Valve

M gate valves feature a non-rising stem with an expanding gate design to provide safe, dependable service in a variety of environments. It is available in flanged or threaded ends in standard bore sizes from 2 1.16. thru 4 1.16. in working pressures of 3,000 psi thru 5,000 psi.

M gate valves come in 7 1.16″ with working pressures of 3,000 psi thru 5,000 psi. Gate valves with different working pressure specifications available upon request.

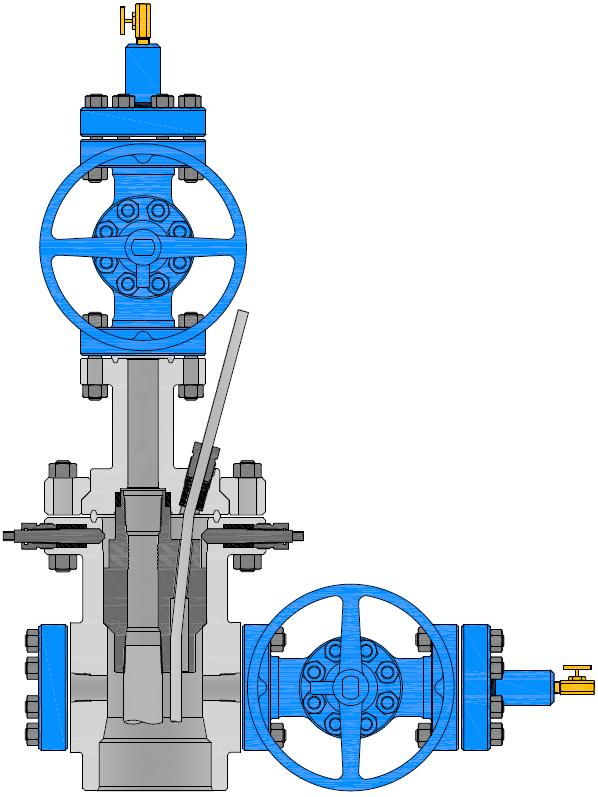

WM-1-Gate Valve

WM-1 gate valves feature a rising balanced stem with an expanding gate design to provide safe dependable service in a variety of environments. It is available in flanged ends in standard bore sizes from 1 13.16″ thru 4 1.16″ in 10,000 psi working pressures.

WM-1 gate valves come in 7 1.16″ with working pressures of 10,000 psi. WM-1 gate valves with different working pressure specifications available upon request.

FC Type Gate Valve

FC gate valves feature a non-rising stem with a slab gate, floating seat ring body bushing design to provide safe dependable service. It is available in flanged ends in standard bore sizes from 1 13.16. thru 7 1.16. in working pressures of 5,000 psi and 15,000 psi.

Frac Systems

Fullbore Drop Ball Wellhead and Frac Head – This surface isolation system allows full-bore passage of frac isolation balls for continuous pumping during multistage fracture treatments. Select Energy Systems integrates its wellhead product line with the frac heads all of which conform to API 6A specifications. The 70MPa (10,000psi) frac head incorporates an integral buffalo head and a ball catch system that does not require flow interruptions during well test and flow back operations. The frac head is compatible with most automatic ball drop systems on the market.

Coiled Tubing Compatible Wellhead and Frac Head – This full-bore frac head and associated wellhead completes the system for your surface isolation requirements during annular coiled tubing fracturing operations. The coiled tubing is protected in the wellhead during annular pumping operations while still allowing full-bore passage of coiled tubing deployed packers and downhole tools. The frac head is rated to 70MPa (10,000psi) and conforms to API 6A specifications.

Observation Wellhead

Observation Wellheads installations have always been a part of most standard pads. The ability to monitor the well is critical while producing. Custom configurations available.